There are four types of failures in the PQP:

2021 PV Module Reliability Scorecard

PQP Failures

Key Takeaways

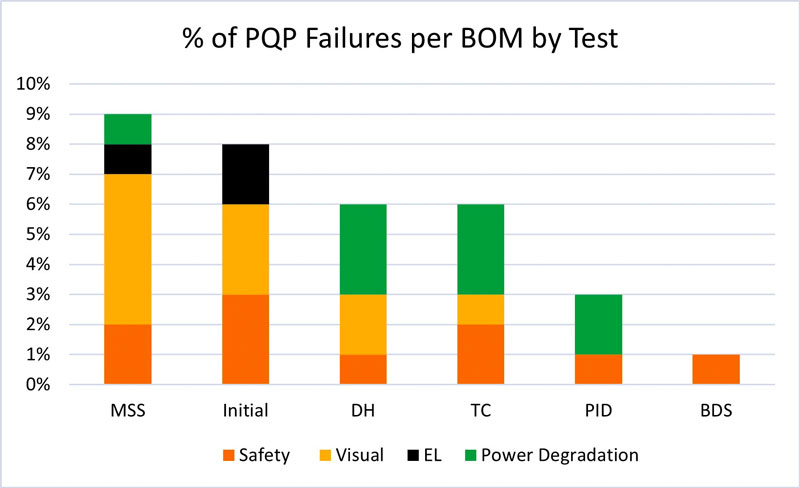

- 26% of BOMs eligible for this year’s Scorecard had at least one failure compared to 20% in 2020.

- One in three manufacturers tested experienced junction box failures versus one in five last year. The majority of these failures occurred during initial characterizations.

- For three successive Scorecards, PVEL has highlighted junction box failures as an increasingly common, yet preventable issue.

- 9% of BOMs experienced failures during the mechanical stress sequence (MSS), more than in any other test. The majority of failures were identified in visual inspection, revealing damaged modules and dislodged junction box lids.

Types of Failure

Safety

Modules with safety failures may be hazardous to operate in the field. Safe operation is determined via wet leakage testing using the IEC 61215 standard, which evaluates the electrical insulation of the PV module.

Visual inspection

Visual inspections identify major manufacturing defects that cause premature field failure. Modules are examined for delamination, corrosion, broken or cracked surfaces and other changes to the module using the IEC 61215 criteria.

Power degradation

Modules with power degradation failures may underperform in the field and ultimately result in financial losses for the asset owner. Although the PQP does not assign specific pass/fail thresholds for degradation, manufacturers may remove products from testing if rates fall below expectations. They typically change BOMs or production processes, then submit new samples for retesting. Retests are clearly noted in PQP reports.

Electroluminescence

Modules undergo EL imaging throughout the PQP test sequences. No pass/fail thresholds are applied to EL images, but manufacturers may discontinue testing if the level of cell damage observed is higher than anticipated. In these cases, PVEL records an EL failure and a new sample may be submitted for retesting.

Junction Box Failures

High junction box failure rates in the PQP are particularly concerning because most failures occurred out-of-the-box before testing. This suggests junction box quality and construction are frequently overlooked during the manufacturing process. Junction box failures included poor sealing of the junction box lid, wet leakage failures originating at the junction box adhesive or pottant, and junction box bypass diode failures.

A possible cause of increased failures is that some junction box production steps are difficult to automate. Junction boxes are usually installed and sealed manually, even in state-of-the-art factories where other processes are automated. Further, before 2018 one junction box per module was typically installed. Most modern modules contain three junction boxes to accommodate the electrical properties of half cut cells, and precise placement is required so as not to shade cells. Imprecise handiwork in this process can result in defects.

Photo courtesy of Photovoltaik Buero

Junction box failures are a long-standing problem for the solar industry.

- $45.33 million USD was awarded in a class action lawsuit against BP Solar and Home Depot for selling modules prone to junction box failure from 1997 to 2007.

- Following 15 rooftop fires, Dutch authorities issued a fire safety warning for 650,000 Scheuten Solar Systems modules in 2013.

Source Details

-

In 2016, reports of charred junction boxes in the field led module manufacturer Solar-Fabrik to advise asset owners to immediately disconnect affected modules due to fire risks.

-

PVEL frequently receives confidential reports of junction box failures in the field and works with customers and partners on technical due diligence for remediation.

- $45.33 million USD was awarded in a class action lawsuit against BP Solar and Home Depot for selling modules prone to junction box failure from 1997 to 2007.

- Following 15 rooftop fires, Dutch authorities issued a fire safety warning for 650,000 Scheuten Solar Systems modules in 2013.

-

In 2016, reports of charred junction boxes in the field led module manufacturer Solar-Fabrik to advise asset owners to immediately disconnect affected modules due to fire risks.

-

PVEL frequently receives confidential reports of junction box failures in the field and works with customers and partners on technical due diligence for remediation.

Source Details

Consulting test data that identifies faulty junction boxes can give buyers valuable insight before procurement decisions are made – and before these defective products are fielded.

Junction box failures are a long-standing problem for the solar industry.

- $45.33 million USD was awarded in a class action lawsuit against BP Solar and Home Depot for selling modules prone to junction box failure from 1997 to 2007.

- Following 15 rooftop fires, Dutch authorities issued a fire safety warning for 650,000 Scheuten Solar Systems modules in 2013.

-

In 2016, reports of charred junction boxes in the field led module manufacturer Solar-Fabrik to advise asset owners to immediately disconnect affected modules due to fire risks.

-

PVEL frequently receives confidential reports of junction box failures in the field and works with customers and partners on technical due diligence for remediation.

Source Details

Consulting test data that identifies faulty junction boxes can give buyers valuable insight before procurement decisions are made – and before these defective products are fielded.

Learn something new?

Share it with your network.