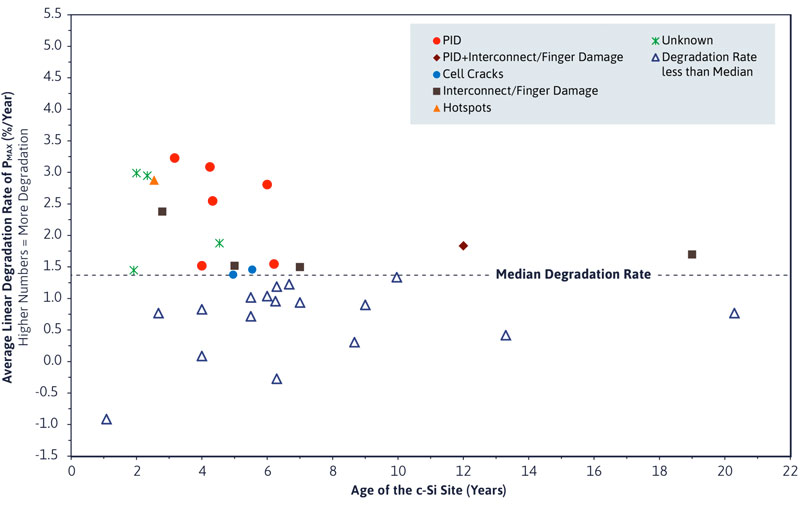

PV modules in younger sites have higher average degradation rates. While PID was a significant factor, projects affected by hotspots and cell cracks also suffered from significant underperformance.

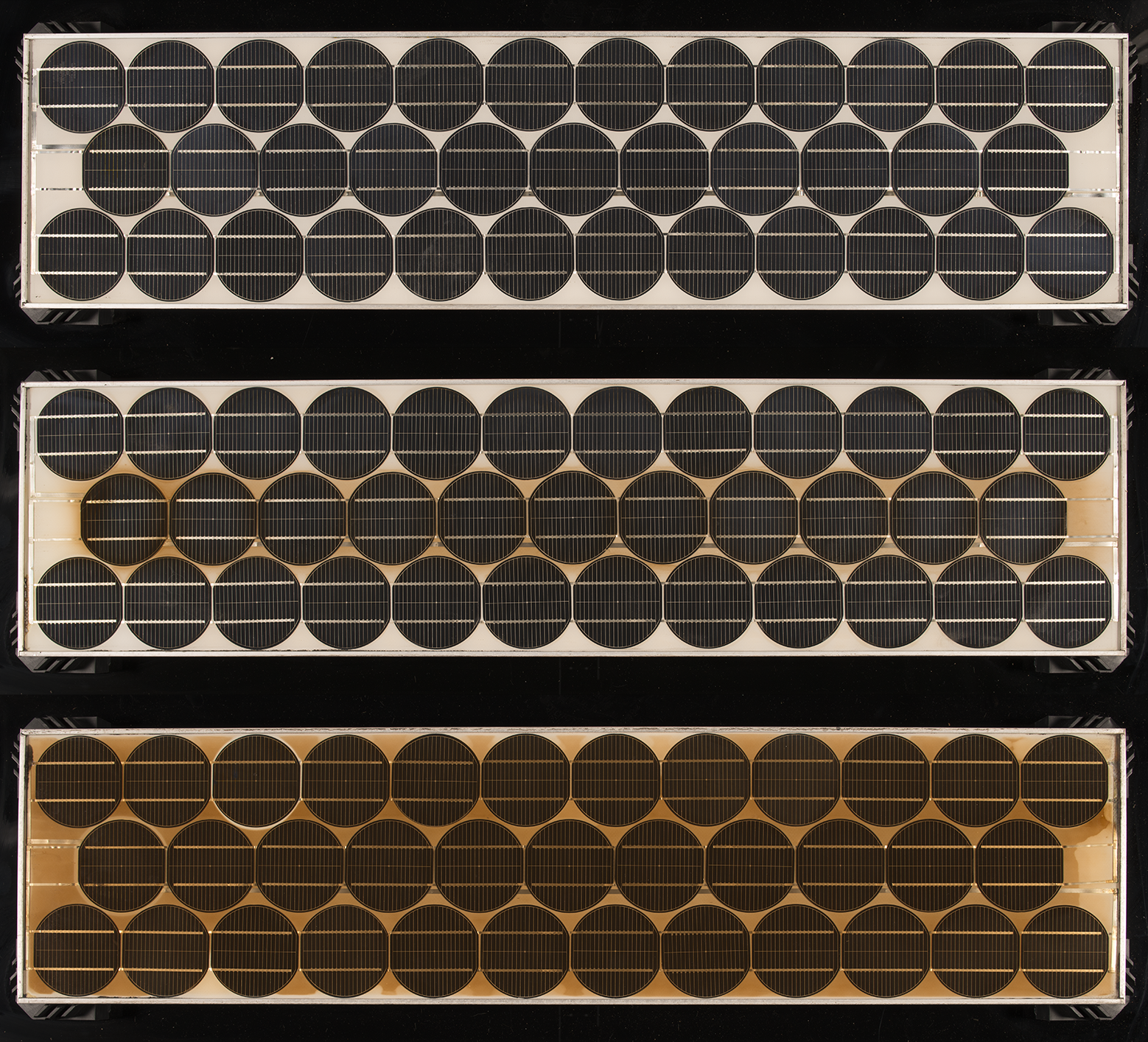

Source: IIT Bombay, NCPRE

Yogeswara Rao Golive, Sachin Zachariah, Rajiv Dubey, Shashwata Chattopadhyay, Sonali Bhaduri, Hemant K. Singh, Anil Kottantharayil, Birinchi Bora, Sanjay Kumar, Tripathi A.K., Vasi Juzer, Narendra Shiradkar, “Analysis of Field Degradation Rates Observed in the All India Survey of PV Module Reliability 2018”, IEEE Journal of Photovoltaics, Vol. 10, Issue 2, pp. 560-567, Mar. 2020.

Yogeswara Rao Golive et al., “All-India Survey of Photovoltaic Module Reliability: 2018”, A Report by the National Centre for Photovoltaic Research and Education (NCPRE), IIT Bombay.