2021 PV Module Reliability Scorecard

Damp Heat

Key Takeaways

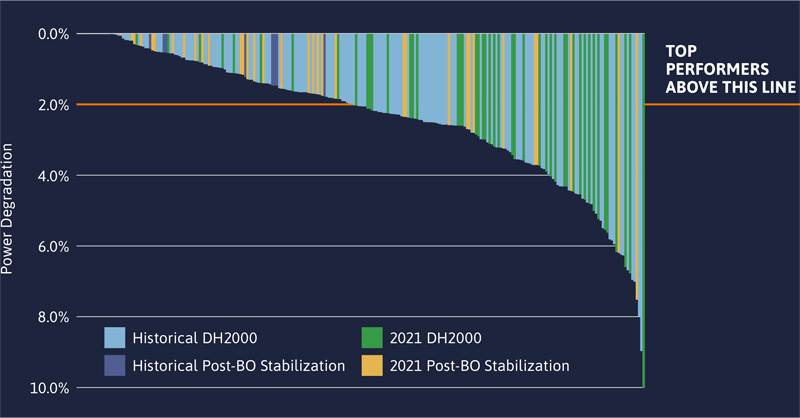

- PVEL’s latest test results indicate that damp heat (DH) remains critical for identifying modules susceptible to moisture ingress, even though the industry has yet to reach consensus on the field relevancy of boron-oxygen (BO) destabilization that is observed in many PERC modules.

- 30% of the Top Performers achieved less than 2% degradation before the 48-hour high-heat, high-current BO stabilization treatment after DH2000. The remaining Top Performers achieved less than 2% degradation after power loss recovery from BO stabilization. Pre- and post-stabilization results are provided in PQP reports to delineate reversible BO-induced degradation from irreversible DH-induced degradation.

- Recovery following BO stabilization is typical, but there are recent DH examples of modules that do not recover or show concerning levels of corrosion leading to significant power loss.

- DH results for glass//glass modules are comparable to glass//backsheet designs, showing that manufacturers have generally overcome early issues with glass//glass designs. For bifacial modules, the amounts of front-side and rear-side power degradation are similar.

2021 Top Performers

Manufacturer

Model Types

BVM6612M-xxxL-H-HC-BF-DG* (BVM6610M-xxxL-H-HC-BF-DG*)

GCL-M3/72GDF* (GCL-M3/60GDF*)

JAM72S10-xxx/MR (JAM78S10-xxx/MR, JAM60S10-xxx/MR)

LGxxxN1C-V5*

SPR-Axxx-COM (SPR‐MAX5‐xxx‐COM) ;

SPR-P3-xxx-COM-1500*

Q.PLUS DUO L-G5.2* (Q.PLUS DUO-G5*) ;

Q.PEAK DUO L-G5.2* (Q.PEAK DUO-G5*) ;

Q.PEAK DUO BLK-G6+/SC* (Q.PEAK DUO BLK-G6+*, Q.PEAK DUO L-G6.2*) ;

Q.PEAK DUO-G7* (Q.PEAK DUO L-G7*) ;

Q.PEAK DUO L-G8.3* (Q.PEAK DUO-G8+*)

Alpha Black* ;

TP3M Black

* Top-performing result achieved after BO stabilization.

Note: Manufacturers are listed in alphabetical order. The tested product is listed first. Variants for which the test results are representative are listed in parentheses. In some cases, test results were not available at the time of publication.

About the Test

Background of the Test

PV modules experience periods of high temperature and humidity not only in tropical and subtropical regions but also in moderate climates. In these conditions, inferior quality components or substandard lamination procedures can lead to degradation or premature failure. The damp heat test replicates degradation and failure mechanisms that can occur in the field.

Test Procedure

The damp heat test subjects modules to a constant 85°C and 85% relative humidity in an environmental chamber for two periods of 1,000 hours—twice the duration required for IEC certification.

The combination of high heat and intense moisture stresses the PV module layers. An environment with high temperature and no current can lead to destabilizing passivated BO complexes within some PERC cells. In the current PQP, to explore this phenomenon PVEL added a post-DH2000 BO stabilization process.

Lessons Learned from Failure

The Problem

When moisture and high temperature weaken the adhesives that bond PV module layers, water, dirt and other foreign materials can enter the module and degrade its internal components.

Projects Facing the Greatest Risk

Humid subtropical zones such as South Africa’s Eastern Cape province and along the Ganges River in India.

How to Detect Failure

If modules in EL images resemble a checkerboard with dark and light cells, that is a sign of BO destabilization. A dark perimeter around some cells indicates that the cells have become susceptible to corrosion.

An Example from the Field

System size: >10 kW

Type: Rooftop

Location: Australia

Failure mode: Delamination

Frequent ground faults began affecting a residential project in a non-coastal region of New South Wales, Australia, just two years after installation. PV modules with faulty layer adhesion were the cause. Half of the monocrystalline PV modules installed had suffered delamination, due to poor materials, poor construction, or both.

PQP testing would have identified this problem prior to procurement.

An Example from the Lab

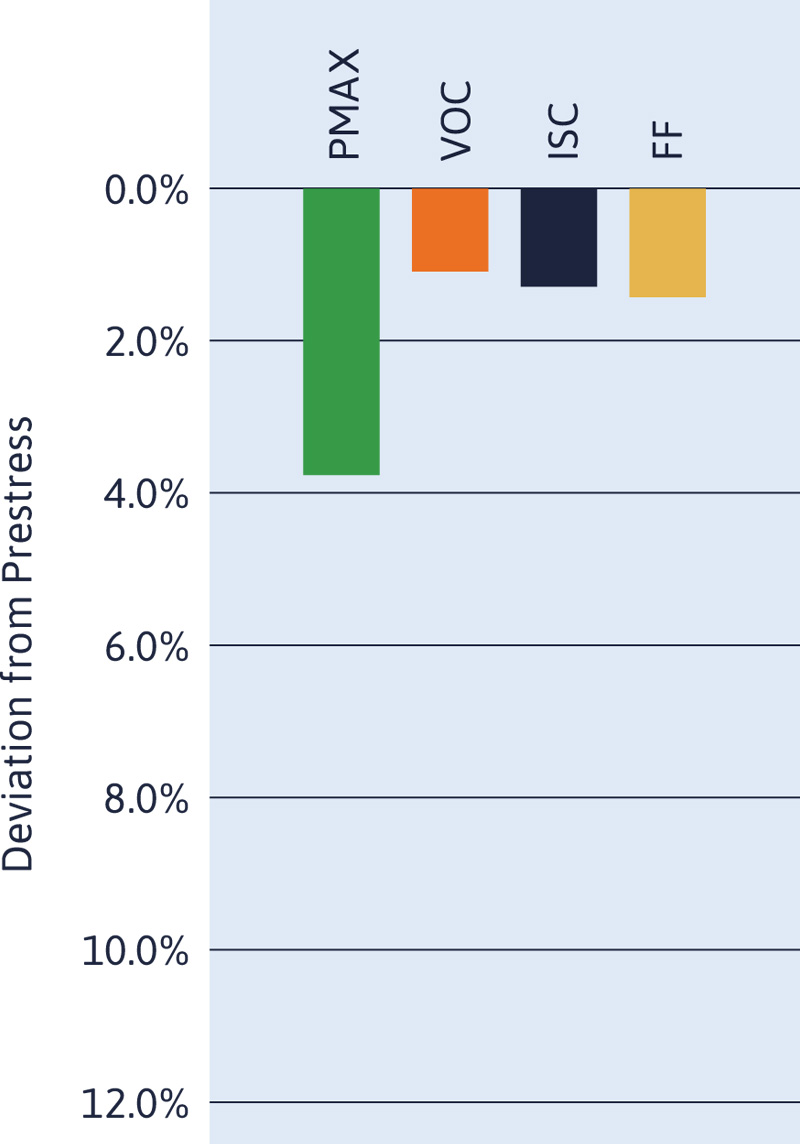

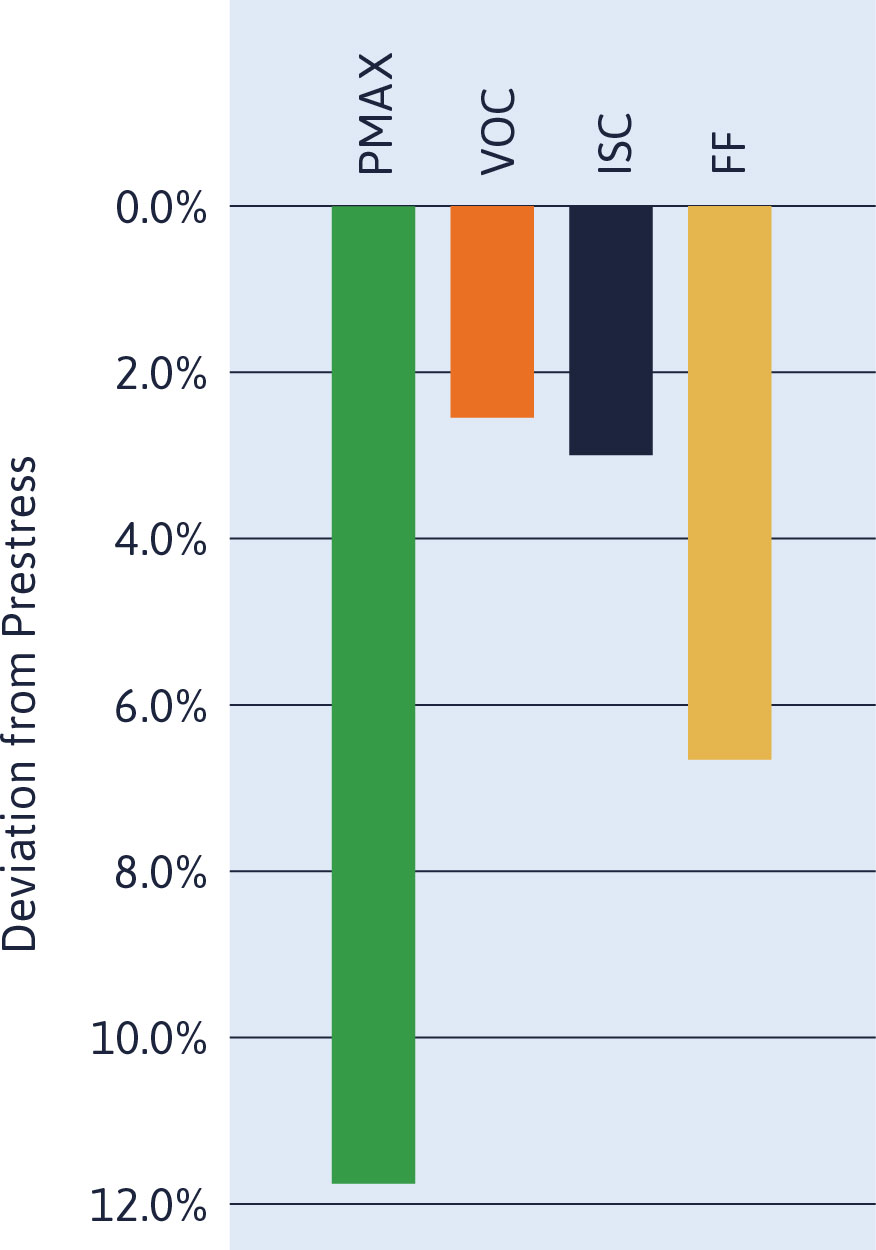

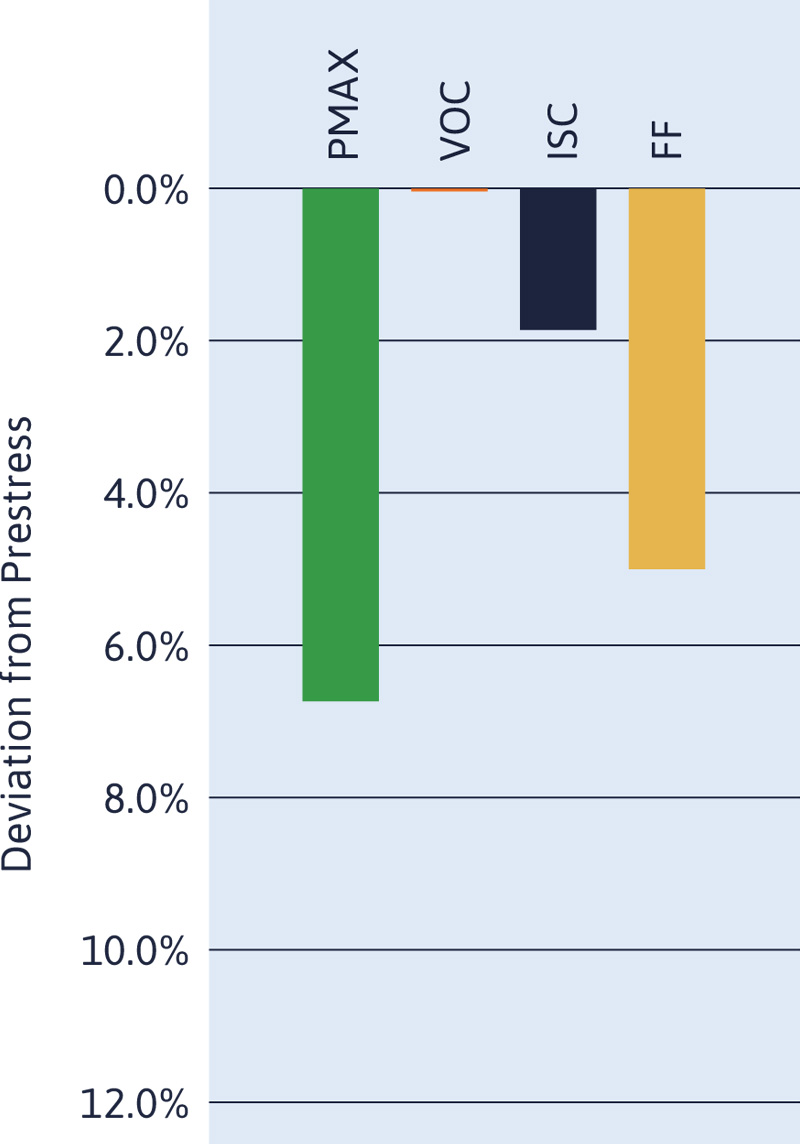

This module completed the 1,000-hour DH test duration with less than 5% power degradation, a result that passes IEC 61215. After another 1,000 hours, power loss soared to 11.7% and did not fully recover after BO stabilization. The checkerboard effect that appears after the DH1000 and DH2000 test sequences is mitigated by BO stabilization, but a dark perimeter remains around many cells.

Expert Opinions on BO Destabilization

PVEL contacted six industry experts for opinions on the field relevancy of BO destabilization. They all agreed that BO destabilization will not occur in the field within the first 10 years. Opinions on the long-term impacts were mixed: half of the respondents expect it will not occur within the lifetime of the module, the other half say it could happen sometime after the first 10 years.

Most experts say BO destabilization is related to the duration the hydrogen exists inside the cell, and that it is very difficult to measure. More research is required, in the lab and in the field.

Power Degradation After:

1,000 hours: 3.8%

2,000 hours: 11.7%

BO stabilization: 6.7%

Learn something new?

Share it with your network.